Company Profile

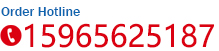

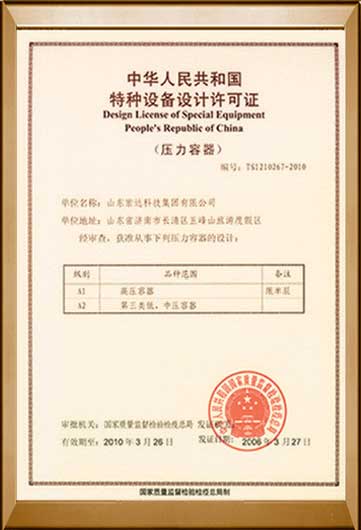

? ? ? ?Shandong Hongda Technology Group Co., Ltd. was established in 1996 with a registered capital of 120 million yuan, focusing on pressure vessels and heat exchangers for the development, design, manufacture and installation. Companies registered trademark "Hongda" in 2005 was named "Shandong famous brand" The company currently has three production plant, covers an area of 211,000 square meters (316 acres), the production workshop building area of 33,000 square meters, the new plant workshop covers an area of 21,000 square meters (including cleaner production workshop 3,200 square meters) of heavy container workshop largest lifting capacity of 200 tons. The company holds A1, design license A2, C2, C3 pressure vessel qualification; A1, A2 grade pressure vessel manufacturing license qualification; US ASME "U" pressure vessel manufacturing licensing; 2,3-level nuclear pressure vessels, heat exchangers manufacture license; ISO9001 quality management system certification. The company won the qualification in the petrochemical market access, network coding 40,127,600; the oil market entry qualifications, entry No. 02021014780; CPECC qualified for; China qualified for Oasis Petroleum; Saipan Italy qualified for the Asian Group; China National Nuclear Corporation qualified for.

Technology Strength

The company currently has Shandong Province provincial engineering technology research center - Shandong Province Heat and Mass Transfer Equipment Engineering Technology Research Center.

Company and Tsinghua University, Shandong University, China's first Institute of Aerospace Technology Group, Shanghai Nuclear Engineering Research and Design Institute and other units to establish a long-term technical cooperation relationship

1. The patent was the case

By the end of 2013, the company has accumulated 24 new product development;

Declared 35 national patents, including patents a.

The company was named China's patent Shandong Star Enterprise, the provincial science and technology outstanding private enterprises.

2. Project Development

National Torch Program 1;

National key new product projects 3;

National science and technology innovation fund for SMEs project 2;

Provincial science and technology research programs and major science and technology projects 4, Spark Program 2.

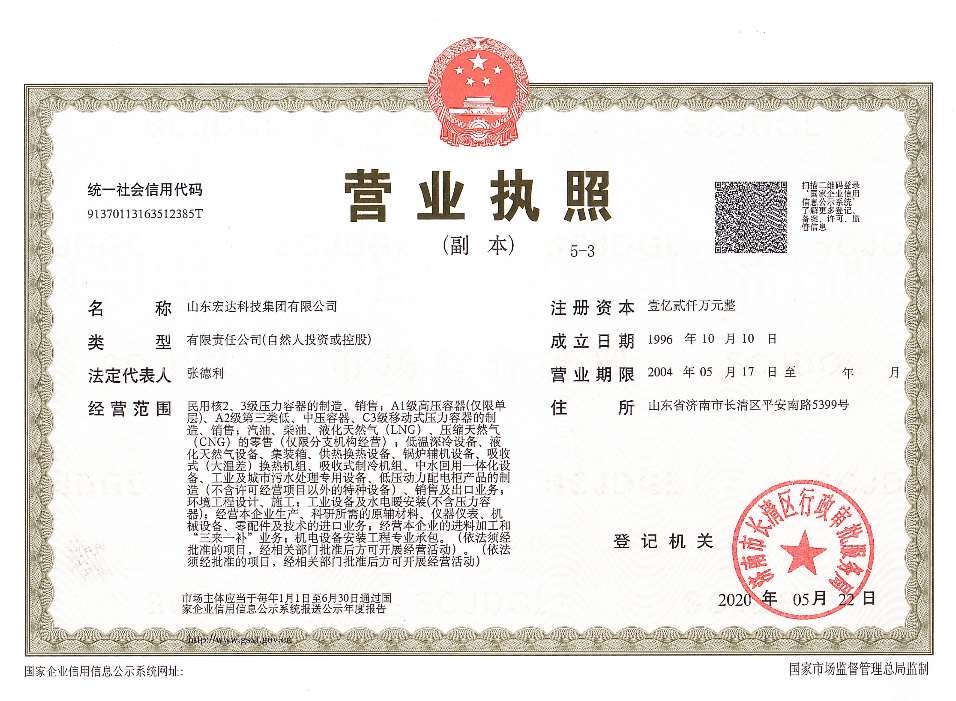

3. Technical Awards

Won: 3 national key new products;

Provincial Science and Technology Progress Award four times;

City of science and technology prize 1;

Municipal Science and Technology prize five times.

Company and Tsinghua University, Shandong University, China's first Institute of Aerospace Technology Group, Shanghai Nuclear Engineering Research and Design Institute and other units to establish a long-term technical cooperation relationship

1. The patent was the case

By the end of 2013, the company has accumulated 24 new product development;

Declared 35 national patents, including patents a.

The company was named China's patent Shandong Star Enterprise, the provincial science and technology outstanding private enterprises.

2. Project Development

National Torch Program 1;

National key new product projects 3;

National science and technology innovation fund for SMEs project 2;

Provincial science and technology research programs and major science and technology projects 4, Spark Program 2.

3. Technical Awards

Won: 3 national key new products;

Provincial Science and Technology Progress Award four times;

City of science and technology prize 1;

Municipal Science and Technology prize five times.

Production Capacity

The main production facilities have 20,000 tons, 15,000 tons presses, cold roll 150mm / HRC 220mm × 3.2m CNC bending machine, 5m × 5.5m × 26m CNC gas heat treatment furnace, 6m × 6m narrow gap welding machine, 16m planing machine, Φ5m vertical lathe, 3m × 3m CNC high-speed drill, Germany Messer CNC plasma cutting machines, tubes tube sheet automatic welding machine, Siemens CNC milling machine and so on.

A total of 58 certified welders:

The State Bureau of Quality Supervision issuing 58;

NNSA issuing 11 people.

Welding procedure qualification total 247, of which:

15CrMo welding Comment 10;

20MnMo welding comment 13;

Comment 5 12Cr1MoV welding;

13MnNiMoR welding comment 12.

Welding procedure qualification nuclear grade 18;

Nuclear grade products Expanding Technology 2.

A total of 58 certified welders:

The State Bureau of Quality Supervision issuing 58;

NNSA issuing 11 people.

Welding procedure qualification total 247, of which:

15CrMo welding Comment 10;

20MnMo welding comment 13;

Comment 5 12Cr1MoV welding;

13MnNiMoR welding comment 12.

Welding procedure qualification nuclear grade 18;

Nuclear grade products Expanding Technology 2.

Warranty Ability

The company's main test, test equipment Shimadzu direct-reading spectrometer, a portable spectrometer, metallurgical microscope, CNC metal diffusible hydrogen analyzer, digital ultrasonic flaw detector, X-ray detector, γ-ray detectors Co60, vacuum helium mass spectrometer leak detector, halogen leak detector, ferrite meter, the film thickness and the like.

The company can independently:

Metallurgical analysis;

Spectral analysis of chemical elements;

-196 ℃ low temperature impact test;

Between stainless steel weld corrosion test;

Weld metal diffusible hydrogen content determination;

Electrode Coating Determination of moisture;

Vacuum helium leak;

And other routine test items.

The State Bureau of Quality Supervision, NNSA certification of NDT personnel:

RT testing Ⅲ grade 1, Ⅲ grade 1 UT flaw detection;

MT testing Ⅲ grade 1, Ⅲ grade 1 PT testing;

RT Level Ⅱ testing five (nuclear grade 3);

UT flaw Ⅱ grade 3 (nuclear grade 2);

Ⅱ grade 5 PT testing (nuclear grade 3);

Ⅱ grade 5 PT testing (nuclear grade 3);

Ⅱ grade nuclear tests examine LT 3;

VT testing of nuclear grade Ⅱ grade 4 people.

The company can independently:

Metallurgical analysis;

Spectral analysis of chemical elements;

-196 ℃ low temperature impact test;

Between stainless steel weld corrosion test;

Weld metal diffusible hydrogen content determination;

Electrode Coating Determination of moisture;

Vacuum helium leak;

And other routine test items.

The State Bureau of Quality Supervision, NNSA certification of NDT personnel:

RT testing Ⅲ grade 1, Ⅲ grade 1 UT flaw detection;

MT testing Ⅲ grade 1, Ⅲ grade 1 PT testing;

RT Level Ⅱ testing five (nuclear grade 3);

UT flaw Ⅱ grade 3 (nuclear grade 2);

Ⅱ grade 5 PT testing (nuclear grade 3);

Ⅱ grade 5 PT testing (nuclear grade 3);

Ⅱ grade nuclear tests examine LT 3;

VT testing of nuclear grade Ⅱ grade 4 people.